SYLVANIX DIY Capped WPC Decking Tile 共擠塑木方格地板 – T1L

$60.00 $45.00

數量(支)/ Quantity (piece)

*以上價格不含運費,有關運送詳情 請查閱送貨需知。

^送貨上門服務、無電梯設備的樓宇、香港特定地區、離島和偏遠地區司機將收取附加費。

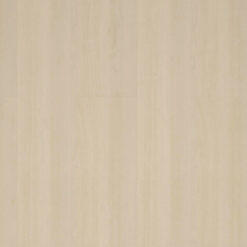

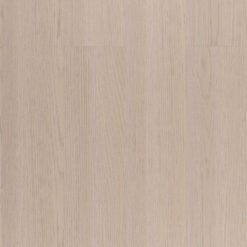

* 由於攝影光源或您的顯示器設置,產品的實際顏色可能略有不同。

*Prices above do not include delivery. Please see our delivery information page.

^Home delivery service, buildings without elevator equipment, specific areas in Hong Kong, other outlying islands and remote areas of the delivery address, drivers will be surcharge.

* Actual Color of product may slightly vary due to photographic lighting sources of your monitor settings.

Sylvanix 是開發和製造環保先進複合材料的領先創新者。 Sylvanix 正在為複合地板行業製定卓越和環境可持續性的新標準。 他們不斷致力於增強和完善我們產品的性能和美觀。 Sylvanix 地板具有天然木材的所有美感以及復合地板的實用性和長使用壽命。

享受傳統木地板的外觀和感覺,只需最少的維護並減少對環境的影響。 Sylvanix 地板是木材的現代替代品,具有永恆的美感和無限的可能性,可以定義任何空間的任何風格。

Sylvanix L Collection 第二代覆蓋(共擠)戶外塑木地板是現今為止市場上最好的戶外地板解決方案。覆蓋或共擠核芯增加進一步的耐用性和抵抗大自然最嚴酷的元素,如黴菌和陽光。這確保了您的新戶外地板確實提供了一種低維護或無需維護的地板解決方案,能夠抵抗紫外線褪色、染色、黴菌。

| 已通過EN 15534:2014第4.4節和EN 15534-1:2014+A1:2017 BS第6.4.3節防滑性測試,達到C級,測試結果為 ≥ 35.1° |

| 已通過 EN 15534-1:2014第8.5.5條和ISO 16869:2008的抗變色微真菌測試,並達到無菌生長的0等級,材料證明可抵抗真菌侵襲 |

| 已通過 EN 319:1993黏合強度測試,平均最大載荷達到8613 N,平均黏合強度達到3.4 Mpa |

| 已通過 EN 15534-1:2014 Clause 9.2和ISO 11359-2:1999的線性熱膨脹係數(-20°~80°)測試,平均值為 32.4×10-6 6K-1 |

| 經 EN ISO 11925-2:2010對火反應 – 直接受火的建築製品可燃性,單一火焰源測試結果,Largest Fs in 20s:表面暴露21毫米,邊緣暴露27毫米 |

| 經 EN ISO 9239-1:2010 火災測試的反應,臨界通量為:橫向 3.6 kW/m2,縱向 3.1 kW/m2。 產煙量 477%min |

| 複合結構可防止開裂、開裂和腐爛。 四面覆蓋共擠保護層可防止染色和褪色 |

| 具有卓越的防污、防褪色、防括和防霉性能 |

| 不會變形、腐爛或導致碎片化 |

| 不需要上油或打磨,維護成本低,容易清 |

| 零甲醛 |

| 表面處理: 木紋壓花 |

| 規格: 300mm x 24mm x 300mm (1 平方呎) |

Sylvanix is a leading innovator in the development and manufacturing of eco-friendly, advanced composite materials. Sylvanix is setting new standards of excellence and environmental sustainability in the composite decking industry. They are constantly working to enhance and refine the performance and aesthetics of our products. Sylvanix Decking offers all the beauty of natural wood with the practicality and long life of composite decking.

Enjoy the look and feel of traditional wood decking with minimal maintenance and a reduced environmental impact. Sylvanix decking is the modern alternative to wood, offering ageless beauty and endless possibilities to define any style, for any space.

Sylvanix L Collection 2nd Generation Capped (Co-Extrusion) WPC Decking Board is by the far the best decking solution the market has to offer. The capped or Co-Extrusion core adds further durability and resistance to mother nature’s harshest elements such as mould and sunlight. This ensured that your new composite deck did indeed offer a low or no maintenance decking solution able to resist UV fade, staining, mould.

| Passed the slipperiness test of section 4.4 of EN 15534:2014 and section 6.4.3 of BS EN 15534-1:2014+A1:2017, and reached Class C, test result ≥35.1° |

| Passed the Resistance against discolouring micro-fungi test of EN 15534-1:2014 Clause 8.5.5 and ISO 16869:2008, and reached level 0 of aseptic growth, proving that the material can resist fungal attack |

| Passed the Bond strength test of EN 319:1993, average maximum load reached to 8613 N and average bond strength reached to 3.4 Mpa |

| Passed the Linear thermal expansion coefficient (-20°~80°) test of EN 15534-1:2014 Clause 9.2 and ISO 11359-2:1999, mean value 32.4×10-6 6K-1 |

| Reaction to fire tests-ignitability of EN ISO 11925-2:2010, Largest Fs in 20s: surface exposure 21mm and edge exposure 27mm |

| Reaction to fire test of EN ISO 9239-1:2010, Critical flux: transverse 3.6 kW/m2 and longitudinal 3.1 kW/m2. Smoke production 477%min |

| Composite construction prevents splintering, crackin and decay. Three-sided durable co-extruded cap layer resists staining and fading |

| Offers superior stain, fade, stratch and mould resistance |

| Doesn’t warp, rot or cause splinters |

| Doesn’t require oiling or sanding, low maintenance and easy to clean |

| Free formaldehyde |

| Surface: Wood Grain Embossed |

| Dimension: 300mm x 24mm x 300mm (1 ft2) |

| 尺寸 | 300mm x 24mm x 300mm |

相關商品

DeHome 8mm

DeHome 10.5mm

DeHome 8mm

DeHome 8mm

DeHome 10.5mm

DeHome 8mm

DeHome 10.5mm

DeHome 8mm

商品評價

目前沒有評價。